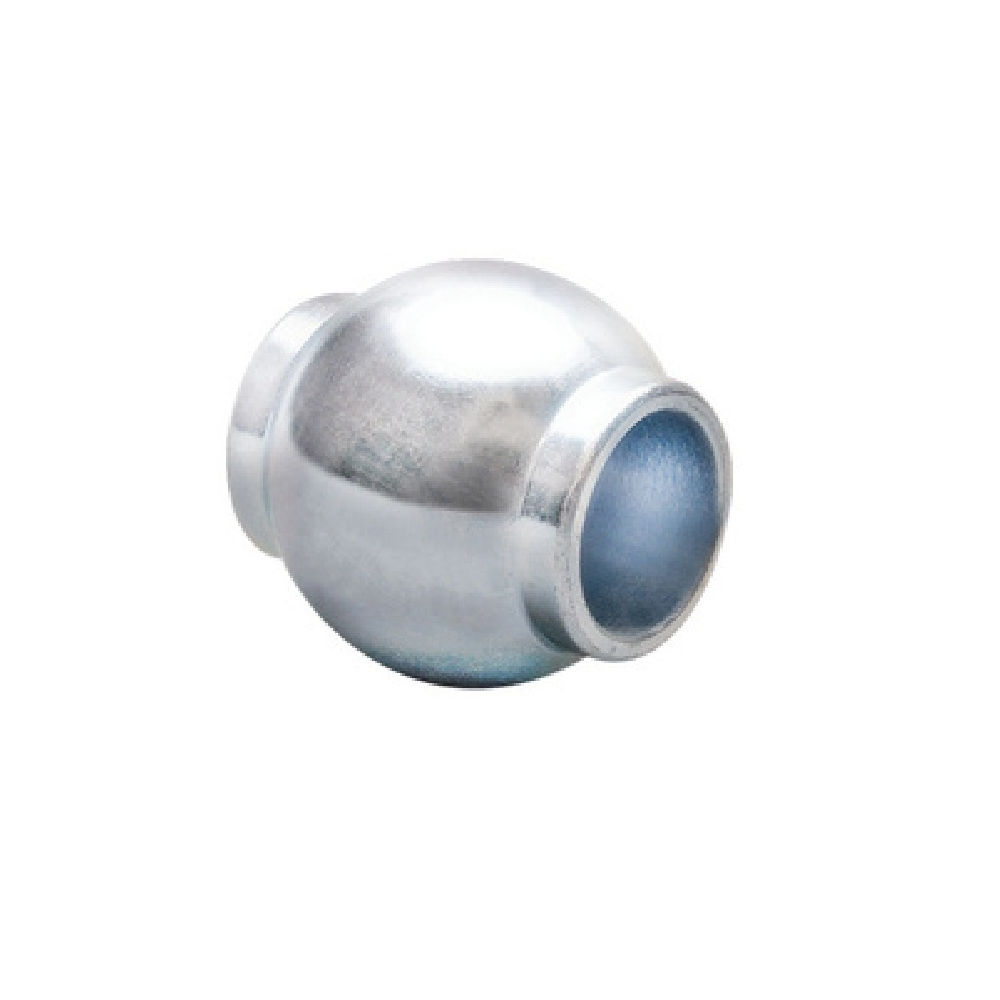

A replacement ball is a critical component used in various mechanical systems to facilitate smooth, rolling motion or spherical movement. Typically found in applications ranging from automotive to industrial machinery, these balls are integral parts of bearings, joints, valves, and other mechanisms requiring rotation or articulation.

Types of Replacement Balls: Replacement balls come in various materials, including steel, ceramic, and plastic, each offering distinct properties suited to different applications. Steel balls, often hardened for durability, are ubiquitous due to their high load-bearing capacity and resistance to wear. Ceramic balls, prized for their lightweight composition and corrosion resistance, are increasingly favored in specialized applications where speed and efficiency are paramount. Plastic balls, on the other hand, are chosen for their non-conductive and corrosion-resistant qualities, making them ideal for specific industrial and environmental conditions.

Applications: The applications for replacement balls are diverse, spanning industries such as automotive, aerospace, manufacturing, and agriculture. They are commonly found in bearings to reduce friction and facilitate smooth rotational motion in wheels, conveyor systems, and machinery components. Additionally, replacement balls play crucial roles in ball joints, where they enable articulation and movement in suspension systems, steering assemblies, and robotic arms. In valves, they act as sealing elements, controlling the flow of fluids or gases in pipelines and hydraulic systems.

Selection and Maintenance: Selecting the appropriate replacement ball involves considering factors such as size, material composition, hardness, and load-bearing capacity, as well as environmental conditions like temperature and exposure to corrosive substances. Proper installation and maintenance are essential to ensure optimal performance and longevity. This may include lubrication, periodic inspection for wear or damage, and timely replacement when necessary.

Sourcing: Replacement balls can be obtained from specialized manufacturers, distributors, and suppliers of industrial components and maintenance supplies. It’s crucial to source replacement balls that meet the required specifications and quality standards for the intended application, ensuring reliability, safety, and efficiency in operation.

In summary, replacement balls are indispensable components in many mechanical systems, contributing to smooth operation, reduced friction, and extended service life when chosen, installed, and maintained appropriately.

Reviews

There are no reviews yet.