Transmission components are integral parts of an automobile’s transmission system, responsible for transferring power from the engine to the wheels at varying speeds. Auto component forging plays a significant role in the production of these components due to the need for high strength, precision, and durability. Here’s a brief overview of the use of transmission components in auto component forging:

Functionality: Transmission components encompass a wide range of parts that enable the transmission system to operate efficiently. These include gears, shafts, shift forks, synchronizer hubs, and various other components that facilitate gear shifting, power transfer, and torque management within the transmission.

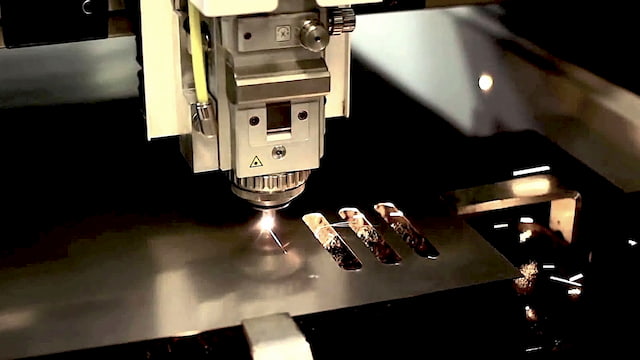

Production Process: Auto component forging is a common manufacturing method for producing transmission components due to its ability to produce parts with high strength and dimensional accuracy. During the forging process, metal billets or ingots are heated to a high temperature and then shaped using compressive forces applied by forging dies. This process allows for the creation of intricate shapes and precise geometries required for transmission components.

Advantages of Forging: Forging offers several advantages for the production of transmission components:

- Strength and Durability: Forged transmission components exhibit excellent mechanical properties, including high strength, toughness, and fatigue resistance, essential for withstanding the high loads and stresses encountered in transmission systems.

- Precision and Dimensional Accuracy: Forging processes produce transmission components with precise dimensions and tight tolerances, ensuring proper fit and alignment within the transmission assembly.

- Material Utilization: Forging minimizes material waste by utilizing the metal’s grain structure to achieve the desired component shape efficiently.

Applications: Transmission components produced through forging are used in various types of transmissions, including manual transmissions, automatic transmissions, continuously variable transmissions (CVTs), and dual-clutch transmissions (DCTs). These components play critical roles in gear engagement, power transfer, and overall transmission performance.

Examples of Forged Transmission Components:

- Gear blanks and gear teeth

- Transmission shafts and axles

- Shift forks and synchronizer hubs

- Clutch plates and discs

In summary, auto component forging is an essential manufacturing process for producing transmission components with the required strength, durability, and precision for optimal transmission system performance. With its advantages in strength, dimensional accuracy, and material utilization, forging remains a preferred method for manufacturing a wide range of transmission components used in various types of automobiles.

Reviews

There are no reviews yet.