Cross shafts play a crucial role in various automotive systems, and their production often involves auto component forging. These shafts are essential for transmitting rotational motion or power between different components within a vehicle’s drivetrain, suspension, or steering systems. Here’s a brief overview of cross shaft use in auto component forging:

Functionality: Cross shafts are mechanical components used to transfer rotational motion or power between two or more components within an automotive system. They typically feature a cylindrical or hexagonal-shaped shaft with one or more mounting points or splines at each end to connect to other components. Cross shafts may be used in applications such as steering linkages, suspension systems, clutch assemblies, and transmission linkages.

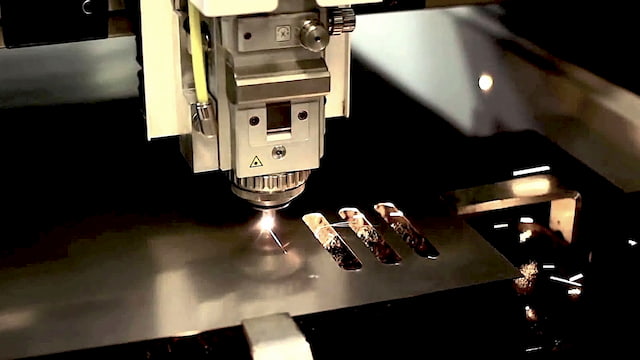

Production Process: The production of cross shafts often involves auto component forging, a manufacturing process that shapes metal using compressive forces. During forging, a metal billet or ingot is heated to a high temperature and then subjected to compressive forces using forging dies to shape the material into the desired cross shaft form. Different forging techniques, such as closed-die forging or impression-die forging, may be used depending on the complexity and size of the shaft.

Reviews

There are no reviews yet.